Joining techniques

Joining techniques

Welding, clinching and clicking: a joining technique for every need

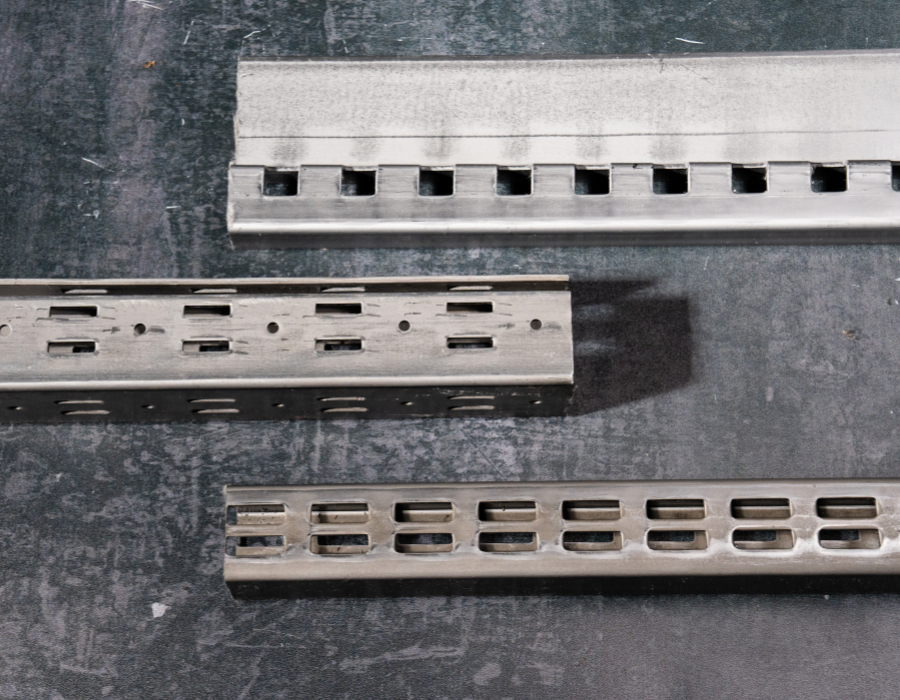

To meet the needs of sectors such as furniture, industrial roller shutters and vehicle cabins, we offer advanced joining techniques such as stapling, clinching and laser welding. These processes make it possible to produce closed metal profiles in galvanised, pre-painted or plastic-coated steel, guaranteeing precision and durability.

Crimping, with a double fold turned and pressed dry, creates hermetically sealed joints by means of grain or herringbone micro-incisions, keeping the surface coatings intact. Clinching uses controlled compression to join adjacent flaps, pressing one on top of the other with pressure proportional to the thickness of the tape. When used together, these techniques offer greater overall strength while fully preserving the quality of the coatings. Laser welding is excellent for those who want a homogenous, rust-resistant joint that eliminates the risk of oxidation. Thanks to this feature, it is ideal for applications requiring a precise finish and long-lasting performance. We offer a combination of technologies to meet every design requirement, balancing strength, precision and aesthetics.

Advantages of advanced joints

- Precision and versatility: Profiles with complex shapes and punched to decimal tolerances.

- Cost and time savings: Elimination of additional machining thanks to ready-made profiles.

- Protection of the coating: Maintaining surface quality thanks to stapling and clinching.

Thanks to innovative technologies and attention to detail, we are a reliable partner for closed metal profiles designed for functionality and durability.

Download our catalogue

The variety, versatility, and quality of our metal profiles,

enclosed in practical and intuitive catalogs.