Plastic coating

Plastic coating

Plastic coating: The Technology that Combines Functionality and Aesthetics

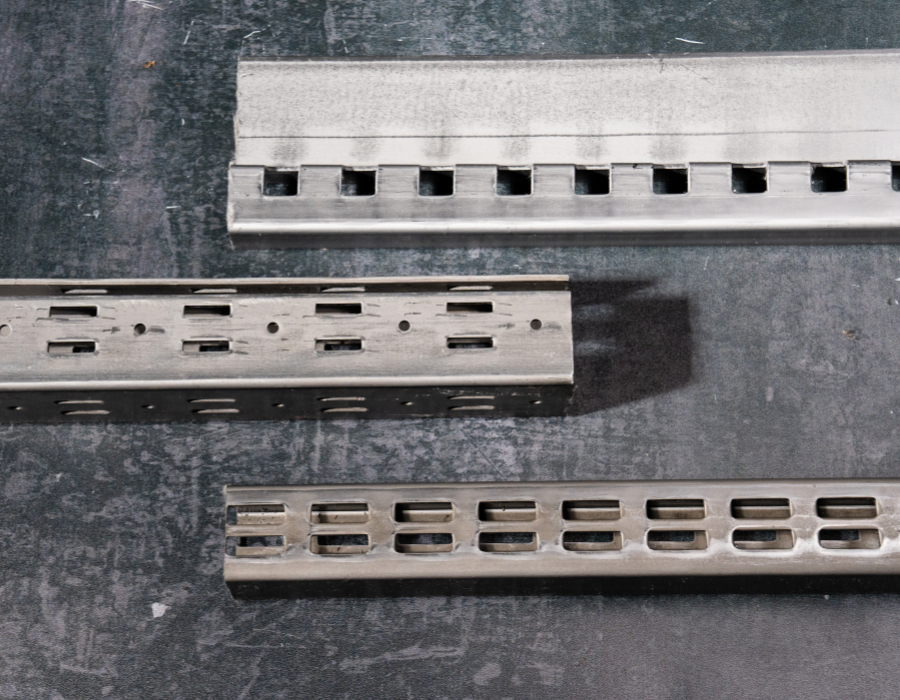

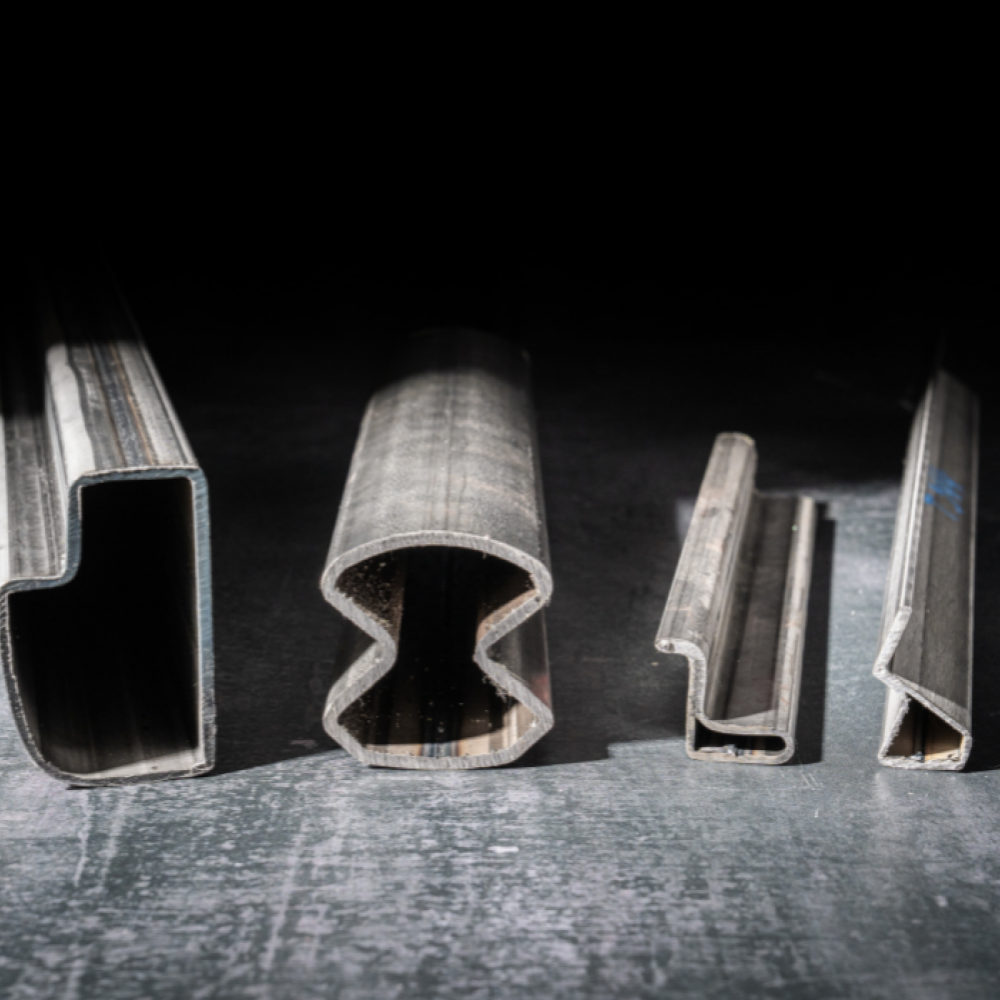

Plasticisation is an advanced process that applies a protective plastic coating to the surface of steel profiles with extreme precision. This treatment not only improves the aesthetics of the product, but also makes it highly resistant to wear, weathering and corrosion, preserving its structural quality and extending its life cycle. Ideal for electrical applications, such as battery racks, plastic coating provides superior insulation and protection, making it perfect for applications requiring durability and high performance.

Advantages of plastic coating

- Corrosion resistance: The plastic coating protects steel from atmospheric agents, chemicals and moisture, reducing the risk of oxidation and corrosion.

- Thermal and electrical insulation: The plastic coating provides an additional layer of insulation, making the profiles suitable for contexts where superior safety performance is required.

- Impact resistance: plastic coating improves impact absorption capacity, reducing the risk of surface damage or deformation.

Plastic coating guarantees uniform and fully customisable finishes, with a wide choice of colours and textures, making it perfect for applications where aesthetics are a key element. This process represents an optimal solution for those who wish to combine high technical performance with refined design, offering results that satisfy even the most demanding market requirements.

Download our catalogue

The variety, versatility, and quality of our metal profiles,

enclosed in practical and intuitive catalogs.