Marking

Marking

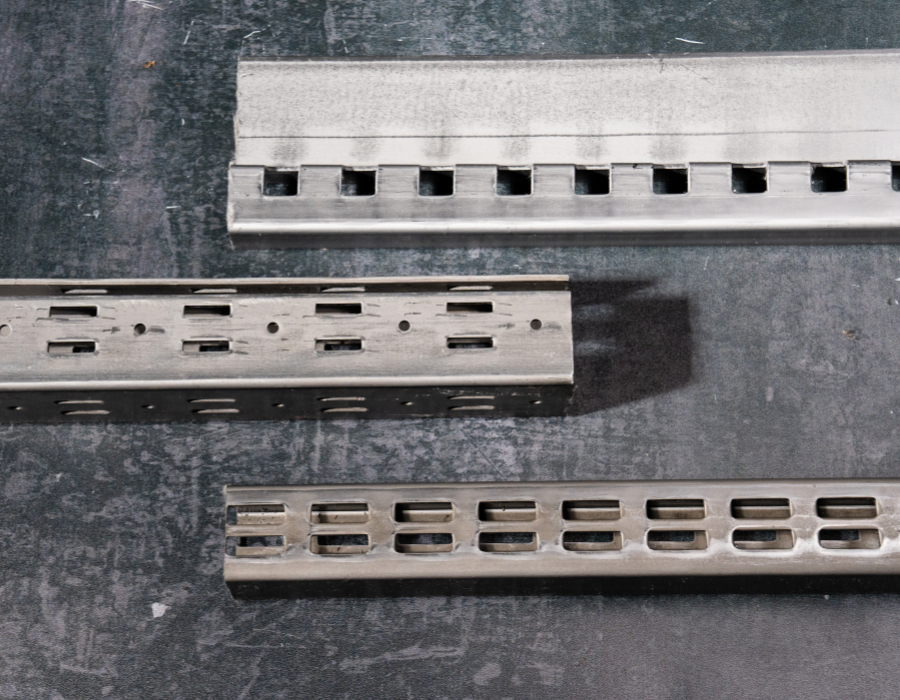

Marking technologies: uniqueness and functionality for steel profiles

Among the many possibilities for customising steel and metal profiles, marking stands out as an essential process for ensuring uniqueness and functionality of products. This process allows lettering, company logos, CE marking and casting codes to be stamped directly on the profile surface, offering added value in terms of brand recognition and optimal traceability throughout the product life cycle. Marking can be achieved through two specific technologies. The first involves the use of a pressure marking roller which, in motion, impresses the characters on the profile thanks to the rotation of the roller with reliefs. This method guarantees uniform and precise marking, ideal for smooth surfaces. The second technique, on the other hand, uses stamping, a solution particularly suited to perforated profiles. In this case, the process combines drilling and marking in a single step, creating direct engravings on the metal strip for complete and effective customisation.

Advantages of the marking process

- Advanced customisation: The possibility of adding lettering or logos allows the profiles to be distinguished and adapted to the specific needs of each customer.

- Brand recognition: Marked profiles become a communication vehicle for corporate identity, increasing brand visibility.

- Precision and durability: The technologies employed ensure sharp and durable markings that are resistant to wear and external agents.

With this processing, we offer tailor-made solutions that combine functionality and design, confirming our commitment to quality and customer satisfaction.