28/06/2022

The guidelines we follow when manufacturing metal profiles

Custom metal profiles: how are they made?

Custom metal profiles are useful in many industries and can be used in a wide range of applications, including in construction, the automotive industry, furniture and the production of movable walls. They can be made of different materials, such as stainless or carbon steel, aluminum and copper, and requested with specific characteristics, thicknesses and sections in order to best meet each customer's needs and to be precisely adapted to any application.

Profilsystem specializes in the production of custom metal profiles, whose dimensions, perforations, lengths and markings can be fully customized. We guarantee the manufacture of products that exactly meet your specifications.

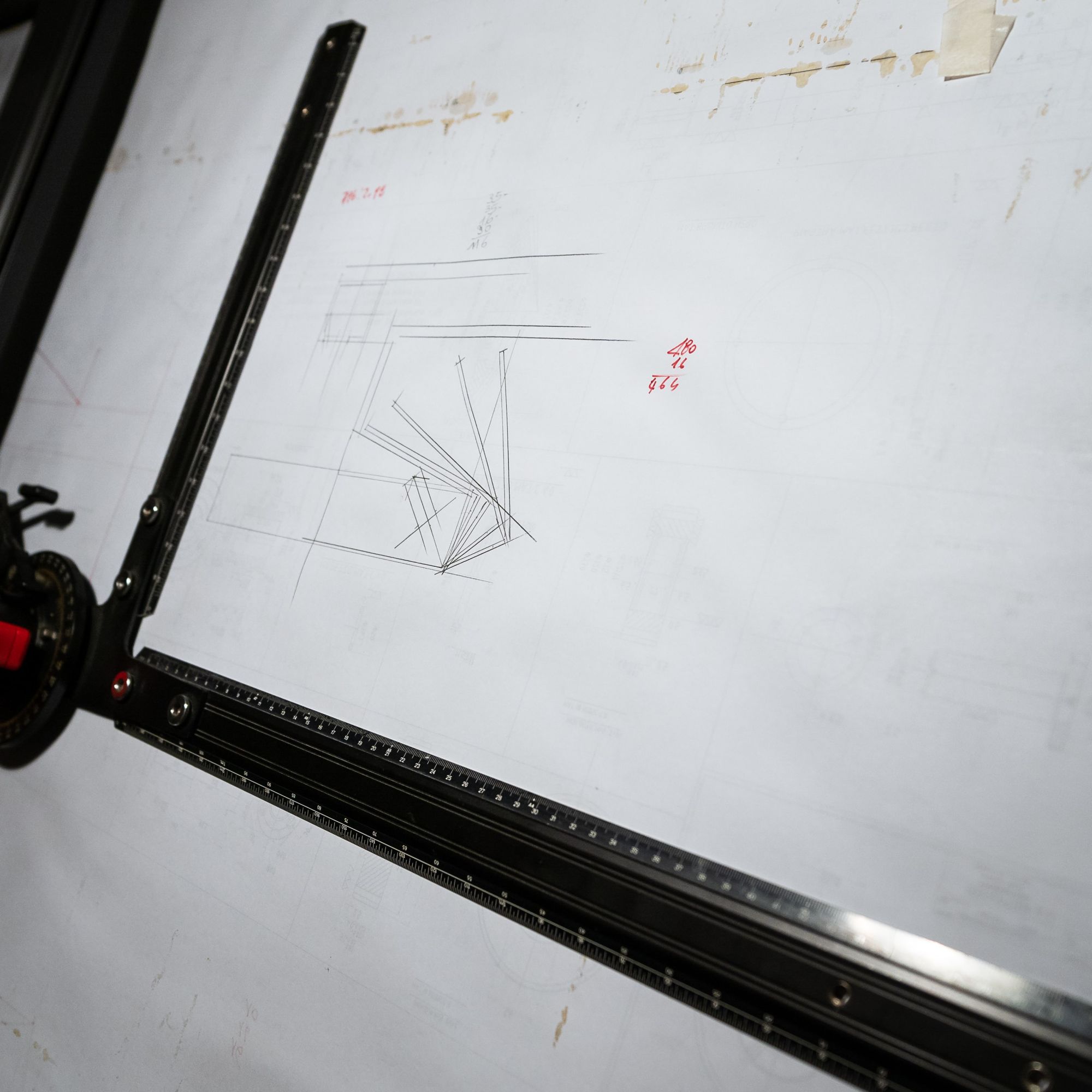

Metal profiles: from design to manufacture

The design and definition of the required shape, or geometric form, is the first step in the proper commercial evaluation of the product. In the case of special profiles which are made to order and are not already available in the wide selection of profiles in our catalog, it is first necessary to perform an initial and quick feasibility survey to find out if we can produce your requested profile in our factories. At this stage, the characteristics required for the manufacture of the profiles are:

- shape;

- quantities required, also based on the production minimums required for the order, which may vary depending on the complexity of the profiles, any additional machining and the type of material. Typically, for commercial profiles or for simple shapes, the minimum quantities range from 30/40 QL (3,000/4,000 kg), which can be reduced to 20 QL (2,000 kg) for stainless steel profiles and 10 QL for aluminum profiles. For custom profiles, on the other hand, minimum quantities are determined at the price quotation stage;

- any customizations, such as lengths (from 450 mm to 13,000 mm), pitch perforations or identification markings on the product (which can be customized with brands or serial numbers);

- material quality;

- special technical and/or quality requirements.

Once these characteristics have been specified, we then can proceed with an accurate and precise technical study to define the costs of the equipment needed to make the required templates. These costs are at the partial expense of the customer's equipment, which ensures its exclusive use, guarantees confidentiality and, if necessary, the coverage of any patents or copyrights. This means constructing an integral part of composite equipment, together with existing equipment, which is therefore integrated and cannot be transferred materially, but only in exclusive and authorized use, and in any case, is compatible with the sequential workloads of the planned production facilities.

After designing and making the equipment, we can then move on to producing customized profiles that precisely meet the requirements of each customer.

Profilsystem can operate within narrow dimensional tolerances, from +/- 0.5 mm up to +/- 0.3 mm. To achieve these results, we use carefully selected, high-quality raw materials to ensure high production yields and the maximum precision of the final product.

Profilsystem metal profiles: quality and expertise to help you build your competitive advantage

With more than 30 years of experience in the industry and a long-standing mission to build a competitive advantage for companies, Profilsystem has created solid, long-lasting partnerships and steadily growing relationships with its customers and partners over time. Established as a family-owned industrial business, Profilsystem promotes international relationships, collaboration and direct and rapid communication to best meet the needs of each customer, thus avoiding bureaucratic interference and always guaranteeing quality, expertise, friendliness and rapid service.

Through continuous investment in the research and development of new technologies and a team of specialized technicians, Profilsystem guarantees efficient and professional services for the design and manufacture of commercial or custom metal profiles and ensures quality sourcing through its relationships with leading international steel manufacturing companies.