Differences between profiling and press brake bending

Differences between profiling and press brake bending

Production of metal profiles: the differences between profiling and press brake bending

The bending process is a plastic forming technique used to shape and permanently deform metal sheets into the desired shape. Following the initial shaping phase, metal bending can be carried out using various methods and specialized machines suited for specific formats.

Depending on the intended use, type, and quantity of required profiles, two distinct processes can be employed: roll forming or press braking.

But how are these processes performed? And what are the main differences between them?

What is press braking?

Press braking is a manufacturing process that bends metal sheets using dedicated press brakes. These machines apply force at specific points, creating a permanent bend without damaging the metal.

Semi-finished products made through press braking are used across numerous industrial sectors. While profiles can vary in size, they have length limitations compared to roll forming and can be manufactured with various bending angles depending on specific usage requirements.

To achieve precise, high-quality results, the process must be performed by skilled operators. The press must apply the correct degree of punch penetration to compensate for the material's elastic springback effectively.

Roll forming: features and advantages

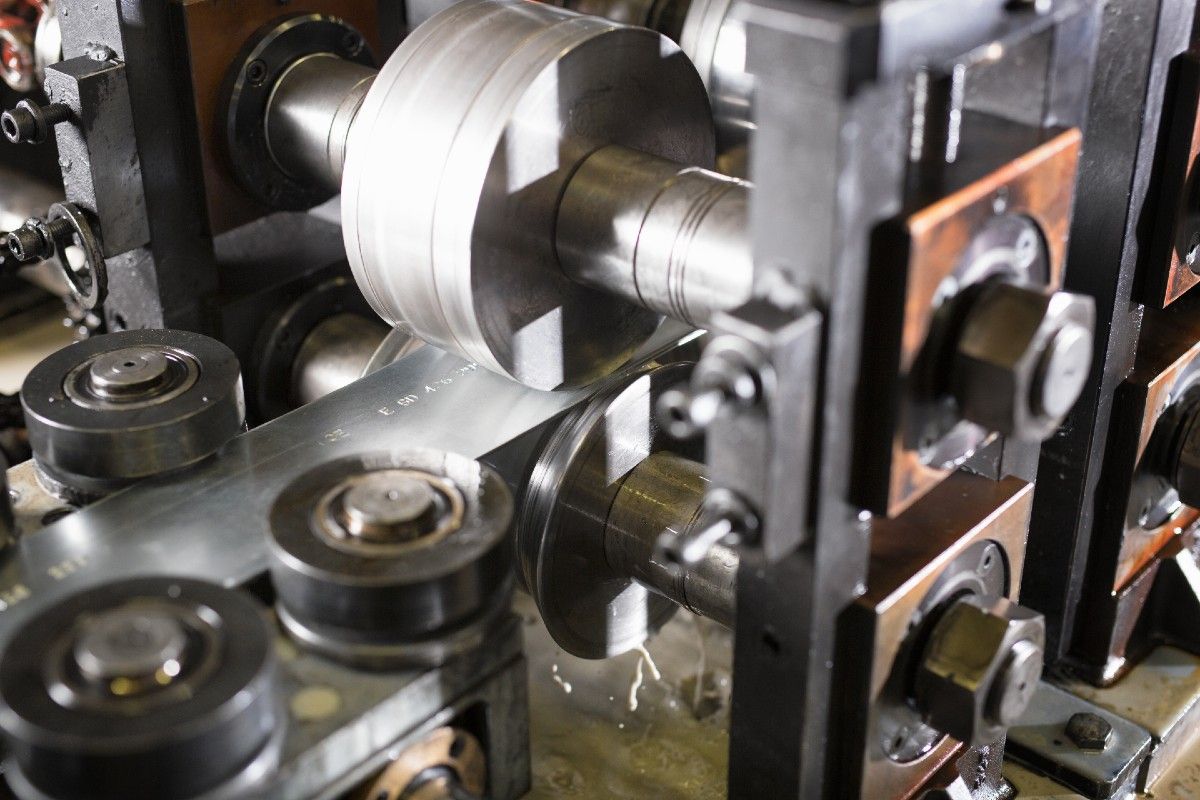

Roll forming, also known as cold forming or shaping, is a continuous bending operation in which metal sheet strips are formed using specialized rollers. The process starts with a flat-rolled strip fed longitudinally into the roll forming machine. The strip is then pulled through powered stations equipped with a series of forming rollers.

As the rollers act on the strip, it is bent and shaped progressively, depending on the number of stations and passes, until achieving complex geometric forms. This method enables the production of custom-designed profiles tailored to specific client requirements, with no limitations on length.

Profiling and pressing: differences

The pressing is best suited for production of limited quantities, works on the strength and hardness of the metal and an excellent solution for the realization of simple profiles with standard lengths. Profiling, on the other hand, works on the elongation of the material and is a process that ensures considerable advantages for the production of large quantities of profiles. For series production, in fact, it allows to significantly reduce costs and processing times, also allowing more customization possibilities and no limit on the lengths of the required profiles. In particular, through the cold forming process, Profilsystem is able to:

- obtain profiles with complex shapes, made according to the specifications required by customers;

- to maintain the mechanical properties of the profile;

- ensure high levels of precision on any type of profile;

- increase production speed with consequent cost reduction.

For more information on press-fitting and profiling processes, customized metal profiles or other services offered by Profilsystem, please contact us. Our staff is always available to guide and advise you in choosing the most suitable solutions for your needs.